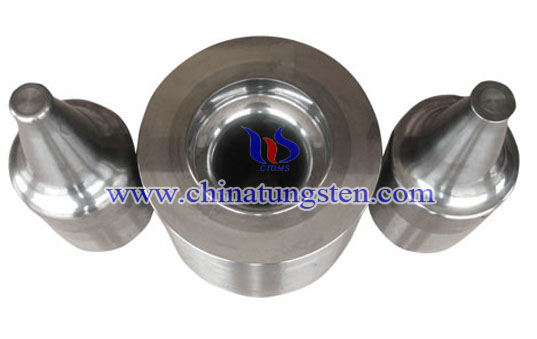

tungsten carbide wire drawing dies

Tungsten carbide wire drawing dies are tools that consists of a highly polished, shaped hole through which wire is drawn to reduce its diameter. The choice of die material, viz, natural or synthetic single crystal diamond, polycrystalline diamond, carbide etc. depends on the material of the wire to be drawn and the operating parameters. Tungsten carbide wire drawing dies are used in wire drawing industries for drawing of different materials like Mild Steel (M.S), High Carbon (H.C), Stainless Steel (S.S), Brass, Aluminium etc.

The art or process of wire drawing like the name implies is to draw a wire of a bigger diameter through a hole with smaller diameter hereby reducing the diameter through plastic deformation while the volume remains the same.In more technical terms it is an operation to produce wire of various sizes within certain specific tolerances. The process involves reducing the diameter of rods or wires by passing them through a series of wire drawing dies with each successive die having smaller bore diameter than the one preceding it. The final wire size is reached as the wire passes through the last die in the series.

All major wire producers use tungsten carbide drawing dies. We can supply different dies, such as drawing die, punching die, extrusion die, cold heading die, which are fully finished or rough cored - cased or uncased, to meet clients exact requirements.

Tungsten carbide wire drawing dies are used for drawing kinds of wire, such as: stainless steel, copper, aluminum, nickel etc. The wire drawing dies we supply including the natural diamond wire drawing dies, PCD wire drawing dies and tungsten carbide wire drawing dies.

Tungsten carbide wire drawing dies advantages:

Wide range of sizes;

Lower cost;

Anti-corrosion and high wear resistance.